The universal joint shaft is an indispensable element of the transmission in a rear- or all-wheel drive car. This node is not too complex in design, but it is very important – without it, the car simply can not move. We tell you the main facts about cardan, frequent malfunctions and ways to avoid them.

What is a cardan shaft and what it is needed for

The cardan shaft, or, more simply, the cardan, is a unit in the transmission of the car, which transmits rotation from the gearbox or transfer case to the gearbox of the driving wheels. If these units were rigidly fixed relative to each other, they could be connected by an ordinary shaft. But in reality, the gearbox and gearboxes are located in different planes in relation to each other, and even can change their mutual position during suspension operation. And the more significantly, the greater the suspension travel.

Therefore, the cardan in the car must be able to transmit rotation at changing angles and distance between the units of the transmission. That is why its device is more complicated than it may seem.

Design and types of cardan transmission

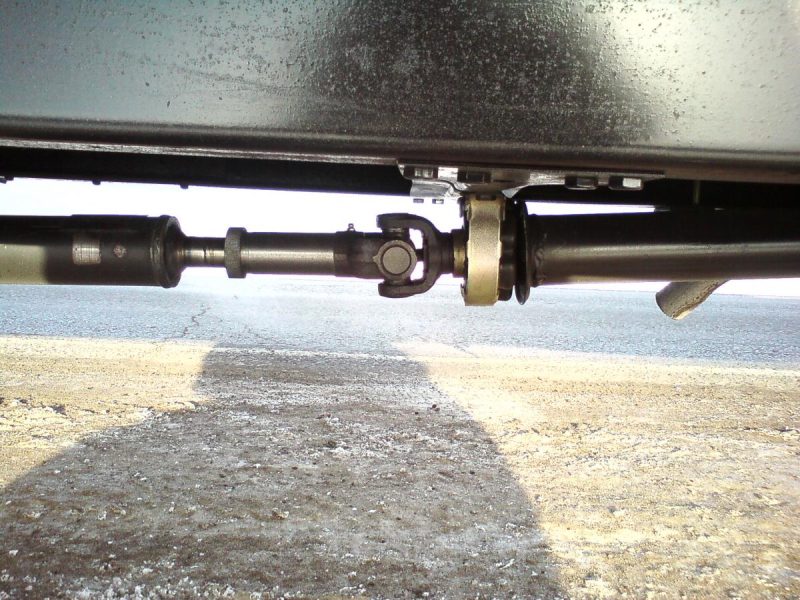

How does the cardan shaft look like? At first glance it seems quite simple, but in fact it includes several important elements. Here is what a cardan shaft consists of:

- tubular shaft or shafts;

- angle joints;

- suspension bearing;

- slot connection;

- elastic coupling.

The main, largest and most noticeable part of the driveshaft is the long tube, which is called the center shaft. With the same rigidity and strength, a hollow tube is lighter than a solid bar.

The simplest and cheapest are single-tube driveshafts. But if the gimbal must be structurally long, it is made multi-shaft from several movably connected pipes. The photo below will help to better understand the structure of the cardan shaft.

To connect the parts of the cardan shaft with each other, angular velocity joints are used. There are at least two of them in a single-tube shaft or more in composite designs.

Most often unequal angular velocity joints are used, which are called crosses because of their characteristic shape. For each cross, the shaft ends and flanges of the transmission are provided with forks – driving and driven. Between them there is a cross with four lugs, each of which contains a needle bearing. Slots and splines are provided for fixation of the structure.

Cardanals with crosses belong to the asynchronous type of cardan gears. The peculiarity of such a joint is the uneven rotation of the driven fork relative to the driving fork, if their axes are not parallel. To put it simply, the driven fork slows down the rotation speed twice and accelerates it twice during one revolution of the driving fork, which creates more vibrations.

The synchronous type includes cardan gears, in the articulation of which are used equal-angle joints, or ball joints, like those used in the drive of the front wheels. Inside them, a fork with several blades meshes with balls rolling in special grooves. This equalizes the speed of rotation. Such driveshafts create less vibration, but are more complicated and noticeably more expensive.

Of exotic designs, one can recall one where rubber couplings are used as a hinge. This option is simple and cheap, but in practice is almost never encountered, because it is not designed to transmit significant torque and does not work with large bends in the drive.

Suspension, or support, bearing is used to support and stabilize the rotation of the gimbal, if it has a composite design.

Since the units connected by the cardan shaft move relative to each other, the cardan device necessarily includes a splined connection. It allows it to change its length in the required range.

Also, the cardan transmission includes a rubber or rubber-metal elastic coupling, which is usually installed in the place of connection to the gearbox. The elasticity of the coupling reduces jerks and vibrations during operation of the mechanism, and protects the transmission from shock loads.

Where the connected units are strongly displaced relative to each other, a cardan shaft with two crosses is installed.

Diagnosis of malfunctions of the cardan shaft

As a rule, wear and malfunction of the cardan shaft when driving is manifested by various noises, as well as vibrations arising from its rapid rotation. Here are the main symptoms and ways to repair your driveshaft.

Clicks, a ringing knock (as on an empty pipe) when touching. Vibrations when accelerating or dropping the gas. Causes:

- Wear and tear of the driveshaft crossmember. It is necessary to replace the cross, there are no other options.

- Wear of splines of the PTO shaft. To eliminate the module with splines or part of the shaft or shaft assembly.

- Loose tightening of bolts fastening the PTO shaft to the flanges of the units. All bolts should be tightened.

Squeak when the shaft is working (its appearance may depend on the angle of operation of the mechanism). Causes:

- The cross joint of the cardan shaft is stuck. It is necessary to replace the joint.

- The ball joint is jammed. If it is slightly worn, it can be rebuilt and lubricated, if it is significantly worn, the joint should be replaced.

Vibration of the cardan when driving. Reasons:

- Unbalance of the cardan shaft. As a rule, this occurs after its incorrect disassembly/assembly with the replacement of cross members or other elements.

- Smoothness violation in the cross joints. It is necessary to replace worn joints.

- Lack of lubrication in the splined joints of the PTO shaft. Disassemble and lubricate the nodes.

- Loss of balancing plates. Eliminated by balancing.

- Mechanical damage to the cardan tube. In this case, it is possible only to replace the part with a new one.

Howling or whistling during operation

The most probable cause is wear of the PTO shaft suspension bearing. It is necessary to replace it.

How to check the condition of the cardan shaft

Diagnosis of the cardan transmission is quite simple, and if you have a pit or an elevator, it is quite possible to carry it out yourself – after all, all the elements are located in plain sight. Here is what to check:

- Traces of mechanical damage on the shaft and other elements of the cardan transmission – they should be absent.

Joints or cross members. There should be no play in them. They can be felt when trying to turn the shaft with your hands or wiggle the tube from side to side. - Pulses of the joints. They must be intact, without tears, cracks and traces of oil squeezing out.

- Elastic coupling. It is inadmissible cracks and even more so tears. It is better to inspect the coupling when turning the shaft.

- Suspension bearing. It should not play and chatter, if you take the two shafts of the gimbal on both sides of the bearing and shake them apart.

- Splined joint. It should have no play – this should be checked by rocking and rotating the shaft.

- The connecting elements of the PTO transmission. Make sure that all fasteners are in place and properly tightened.

Totals

- Cardan shaft is a node in the transmission of the car, which transmits rotation from the gearbox or transfer case to the gearbox of the driving wheels, located in different planes.

- The main elements of the cardan – tubular shaft or shafts, angular velocity joints, suspension bearing, splined joint, elastic coupling

- The main faults of the cardan shaft, such as knocks or extraneous sounds during operation, are associated with wear of its moving elements. Also the gimbal may be out of balance.

- The condition of the elements of the cardan shaft is easy to check independently if you have a pit or a hoist.