In the 2000s, the 1.6-liter EP6 gasoline engine appeared on Peugeot-Citroen cars, which became the cause of numerous complaints and problems of motorists. We made a detailed review about it earlier. In 2009, engineers updated it, after which the index of the atmospheric version was changed to EP6C. It became the basis for equipping the vast majority of cars of the French concern, starting with compact Peugeot 207 or 208, ending with rather large Peugeot 5008 or commercial Citroen Berlingo.

It should be noted that BMW specialists were also involved in the creation of the motor, so after 2010 it appeared on compact BMW 1-Series and 3-Series as the N13 engine. Curiously enough, but the same unit for MINI Cooper already has marking N16 due to some technical changes.

Taking into account the significant age and characteristic shortcomings, this engine in the modernized version EP6F with a turbine continues to be produced in France until now. In particular, it is used to equip cars with hybrid powertrains.

The main visual difference between the restyled version of the motor and the original unit is the oil pressure sensor protruding from the oil filter housing. On the first version of the engine the sensor was not visible, as it was located below the vacuum pump on the rear side of the engine. If we talk about the N13, then here the location of attachments is significantly different due to the longitudinal location of the unit in the underhood space. Accordingly, it will not be possible to put the “German” on French cars or vice versa.

The place for the factory marking and serial numbers is the flywheel cover, slightly below the location of the oil filter. The original marking 5FW has given way to the indexes 5FS or 5F01.

Specifications

| Characteristics | Value |

|---|---|

| Engine displacement, cc | 1598 |

| Maximum power, hp | 90 – 120 |

| Maximum torque, Nm (kgm) at rpm | 132 (13) / 2500 147 (15) / 4000 156 (16) / 4250 160 (16) / 4250 |

| Fuel consumption, l/100 km | 5.9 – 8.2 |

| Engine type | Row, 4-cylinder |

| Additional engine information | Multi-point injection |

| Maximum power, hp (kW) at rpm | 90 (66) / 5500 115 (85) / 6000 120 (88) / 5800 120 (88) / 6000 |

| Compression ratio | 11 |

| Cylinder diameter, mm | 77 |

| Piston stroke, mm | 85.8 |

| CO2 emission, g/km | 135 – 195 |

| Valve drive | DOHC |

| Number of valves per cylinder | 4 |

General level of reliability

Initially, French motorists positioned EP6C as a motor devoid of congenital defects of its predecessor, but in fact it is a deception. The modernized engine was unified in terms of production costs and achieved compliance with Euro-5 environmental standards. Reliability of the power unit remained without any changes. If there are any changes for the better, it is only due to the replacement of individual engine components.

Oil Pump Control Valve

The updated engine has a completely new oil pump, which has two stages of pressure control. It is realized by means of a control solenoid. Power supply wires to it pass through a separate hole, arranged in the crankshaft bed. The hole has a rubber seal and a metal cover. After a while, the rubber dries up, and oil leaks through the bushing, falling on one of the supports of the power unit, and you can notice the leakage only when the protection is removed. In rare cases, oil rises through the wires due to capillary effect up to the ECU, which leads to its short circuit and expensive repair.

If there is a problem, you can simply change the bushing, which costs about 20 dollars or buy a repair kit, which includes the wire to the solenoid, but in this case the price tag will be three times more expensive. Performing work on replacing the seals will require preliminary dismantling of the pallet.

Pump drive

The work of the pump on the EP6, regardless of the year of release, is carried out through an intermediate roller, for which there is its own tensioner, called among masters “guitar”. It ensures the tightness of the roller, both to the belt, thrown on the crankshaft pulley, and the roller mounted on the pump. After the engine upgrade, the tensioner became controllable, instead of passive, which existed originally. It not only has a power supply, but also a servo that allows for self-tensioning of the tensioner. Curiously, but both tensioners can be easily replaced by each other, for example, instead of the active “guitar” on the modernized engine in the process of repair can be installed an old tensioner for motors up to 2009. Similarly, a newer part can be installed on an old motor, only there is nowhere to connect it, so the wire can simply be cut. Tightening the roller in this case is accomplished by a clock spring. In both cases, you will have to pay about 100 dollars for the tensioner.

At a solid price, the tensioner bearing is disgusting, not always able to serve even 50 thousand kilometers. After that, there is an extraneous rumble. On the market there are analog rollers complete with a bearing, the price of a quite decent sample is about 50 dollars.

A possible cause of the rumble may be a worn joint, on which there is a movement of the cage of the roller. In this case, you will have to change the tensioner assembly.

A worn joint becomes the cause of skewing the roller, which in turn leads to accelerated wear of the belt. In the case of its breakage, in some cases, the scraps are wrapped around the crankshaft pulley with the obligatory leakage of oil seals. In general, problems can be very serious, so owners of cars with a 1.6-liter EP6C engine should pay due attention to the condition of the pump.

Pompa

In the case of replacing the tensioner, you should definitely check for play on the pump pulley. In some cases, even if it is present, no extraneous noises occur, but replacement should be carried out without delay.

At the outlet from the pump, a plastic tube is used, which is prone to drying out. Leaks most often appear along the fitting, and it is not easy to notice them visually. The most economical option would be to coat the joints with sealant, but ideally the worn part is better replaced with a new one.

Crankshaft pulley

It is provided with a rubber damper, which positively affects the service life of the pulley, but the rubber quickly deteriorates in case of contact with oil, so it must be monitored. It is necessary to point out the low quality of the front oil seal installed on the crankshaft. Its reliability does not exceed 100 thousand kilometers, after which leaks begin. The owners of cars with EP6C engine have to change it regularly.

Vacuum pump

The absence of the engine throttle together with the use of the Valvetronic system leads to a lack of discharged medium, which requires the installation of a vacuum pump. If it itself is quite reliable, then its tightness leaves much to be desired, leaks are most often fixed on the body or in the places of connection with the cylinder-head. A feature of the pump is its tendency to jam if the crankshaft and other shafts are turned clockwise. To prevent spontaneous development of such a situation, it is forbidden to leave the car on rises “in gear”, if there is a possibility of rolling back. When the pump is stuck, starting the engine leads to breaking off the flange on the drive. This problem was observed on EP6 motors and has persisted after modernization.

Thermostat operation

The electronically controlled thermostat for the “Frenchman” is offered in a set with a splitter housing at a price of about 150 dollars. Often with significant wear or the use of low-quality analogs of the thermostat, there is a mismatch of work with the ECU, as a result of which the motor begins to warm up, or vice versa, does not gain the necessary temperature. It is almost impossible to notice overheating in the early stages, most often the sign of the problem is damage to the valve seats. To avoid such problems, do not pay attention to the cheapest thermostats on the market. It is necessary to take into account and the difference between those for cars with automatic and manual transmission.

The thermostat position provides for limiting the coolant output from the radiator, while in most cars it is set differently, blocking the flow of antifreeze into the radiator until a certain temperature is reached.

A fully functioning thermostat should ensure that the hose approaching the radiator from the top is at a high temperature, while the outlet hose at the bottom remains warm during normal system operation. The presence of a cold hose is a sign of existing problems. If the thermostat does not fulfill the ECU commands, its valve will open in emergency mode, but only after the cooling temperature reaches 105 degrees, and after the radiator (partial cooling). There are also serious complaints about the splitter housing. Made of plastic, it is quite quickly covered with cracks, which leads to losses of antifreeze.

Reverse valve GBT

Below the solenoid valve of the cylinderhead is provided with a plug under the Torx key. It is responsible for a full supply of lubricant to the phase shifters. If the valve gets clogged with deposits of burned oil or any other elements, there will be problems with the operation of phase shifters, expressed primarily with twitching at idle. The cost of a new valve is about $15.

Valve cover

To ventilate the crankcase, the valve cover has a separator with a rubber valve. Over time, the rubber dries, cracks, through the valve into the intake enters additional air, not accounted for by the flow meter. Together with it, oil vapors from under the cover can get into the system. This problem is characteristic of both EP6 and the updated version of the EP6C engine.

The diaphragm is changed to an analog, and the traces of opening the cover remain clearly visible, first of all, the fasteners fly off, which makes you use a variety of improvised means for fastening. The valve cover gasket also loses elasticity as it wears, requiring replacement when the first oil leaks appear.

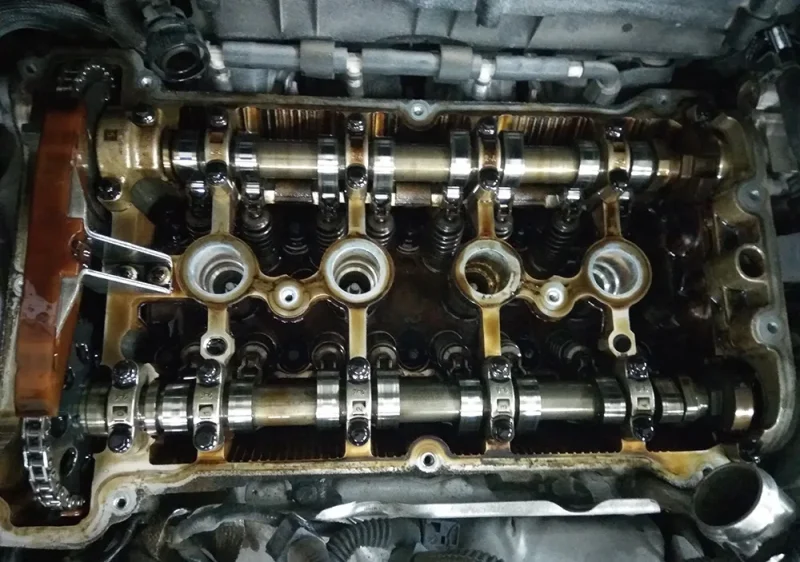

Valvetronic

This system was previously considered in relation to the engines of the German brand BMW. It allows you to control the degree of cylinder filling, changing the maximum values of valve lift at the inlet. The main problem of Valvetronic is accelerated wear of the main elements due to deterioration of lubrication quality. In fact, for all engines with more than 10 thousand kilometers of mileage between oil changes, there is wear of eccentrics, worm gear, even camshafts, and their design provides for two, with a high rate of failure, requiring expensive replacement.

Dirty oil negatively affects the accuracy of the phase shifters and their valves. The initially set service interval of 20 thousand kilometers turned out to be simply destructive for EP6 engines, as a result of which many of them fail without the possibility of repair. The increase in the reliability level of modernized EP6C is largely due not to technical improvements, but to the banal reduction of the manufacturer’s established terms of oil changes every 10 thousand kilometers.

Transmission timing chain

The timing drive is chain, and the change of the chain with a hydraulic tensioner is not tied to engine repair. Most often, when the appearance of grokhod in the replacement needs not the chain, but the hydraulic tensioner. Its cost is about $60, and the replacement process is simplified due to its location on the front side of the power unit.

The chain itself is also affordable, the same $60. In the process of replacement, a new shoe and guides must be supplied, but their cost is also quite affordable. The replacement process does not involve great difficulty, but the camshafts will have to be fixed beforehand. For the crankshaft, fixation is carried out through the flywheel. When removing the chain, the calipers, star are dismantled, which is generally characteristic of the BMW development motor of the 2000s.

The average service life of the chain is about 150 thousand kilometers or three times longer than on EP6 engines. The reason lies only in the improved manufacturing quality of the element itself, and the new chains can be installed without restrictions on prerestyling engines in the process of repair.

Cylinder Block Plug

The cylinder block provides for the presence of a plug in the cooling circuit, hidden from view under the timing cover. Its presence creates additional risks of squeezing out, causing cooling to escape from the system into the sump.

Sealing under the phase shifters

Originally, the O-rings installed on the camshaft under the phase shifter were made of steel. These in turn damaged the cylinder head, leaving behind noticeable grooves. After the engine upgrade, softer Teflon was used for the rings, which eliminates the damage while maintaining the necessary reliability of sealing.

GBZ

Quite a common phenomenon for EP6C motors is oil burning, but the problem lies not in its design flaws, but in the owners’ desire to save on oil. It can get into the cylinders, both through the rings after they are corked, and through the oil caps in the cold state. The latter have recently received improvements to avoid this problem. The cost of the complex is about 55 dollars, plus the cost of carrying out the replacement.

Quite common is the problem of valve seats falling out at the valves, rendering the repair useless. The cause of the problem is prolonged overheating of the cylinder head. The driver is not able to control the situation, as the temperature sensor will show +90 degrees, even in cases where the antifreeze temperature has passed +105 degrees.

A falling out seat will cause the valve to not close and result in a piston strike. If the seat moves only slightly, the problems are somewhat less, there will not be a tight closure of the valve with the occurrence of ignition lapses. These can only be noticed when running hot and with the characteristic whistle of gases bursting through the ajar valve.

Oil pump

The most problematic element of the pump is the pressure control valve. If it fails, the pump is most often left running at maximum capacity. It is possible to determine the existence of a problem only during computer diagnostics, using a Peugeot-Citroen scanner.

Replacing the valve with a new one will require spending 160 dollars on a spare part.

Elements of the piston group

Despite the use of a lightweight piston group, there are no significant complaints about its performance. If the rings sticking occurs, it is solely due to irregularity of oil changes. High mileage between lubrication changes causes wear of liners, and in some cases, the crankshaft.

Totals

If we talk about the reliability of French EP6C motors, then against the background of the original, engineers have not made any constructive changes. More reliable chains and oil caps appeared later, and can be installed on both old and restyled motors. Oil leaks along the crankshaft remain, but the lack of a heat exchanger on the oil filter housing solves the gasket leaking problem. Additional problems include poor reliability of the valve that controls oil pump pressure.

Replacing the above parts with more reliable samples and reducing service intervals allows owners of cars with EP6C motors to reduce the number of their own problems. Practice shows that at the proper level of service and significant annual mileage motors are able to work up to 500 thousand kilometers, which is a very decent indicator.