Characteristics of the M113 engine

| Characteristics | Data |

|---|---|

| Production | Stuttgart-Bad Cannstatt Plant |

| Engine make | M113 |

| Years of production | 1998-2011 |

| Cylinder block material | aluminum |

| Power system | injector |

| Type | V-type |

| Number of cylinders | 8 |

| Valves per cylinder | 3 |

| Piston stroke, mm | 84 |

| Cylinder diameter, mm | 97 |

| Compression ratio | 10 |

| Engine displacement, cc | 4966 |

| Engine power, hp/rpm | 292/5600, 296/5600, 306/5600 |

| Torque, Nm/rpm | 440/2700, 456/2800, 460/2700 |

| Environmental standards | Euro 4 |

| Engine oil | 0W-30, 0W-40, 5W-30, 5W-40, 5W-50, 10W-40, 10W-50, 15W-40, 15W-50 |

| How much oil in the engine, liters | 8.0 |

| When changing pour, l | ~7.5 |

| Oil change is carried out, km | 7000-10000 |

| Engine operating temperature, deg. | ~90 |

| Fuel consumption, l/100 km | – city: 18.9, – highway: 8.9, – mixed: 13.2 |

| Oil consumption, gr./1000 km | to 800 |

| Engine life, thousand km | – according to the factory data: -, in practice: 300+ |

| Tuning, hp | – potential: 500+, without loss of resource: – |

| Motor installed | Mercedes-Benz CL 500 C215, Mercedes-Benz CLK 500 C209, Mercedes-Benz CLS 500 C219, Mercedes-Benz E 500 W211, Mercedes-Benz G 500 W463, Mercedes-Benz ML 500 W163, Mercedes-Benz ML 500 W164, Mercedes-Benz S 500 W220, Mercedes-Benz SL 500 R129, Mercedes-Benz SL 500 R230, Mercedes-Benz R 500 W251 |

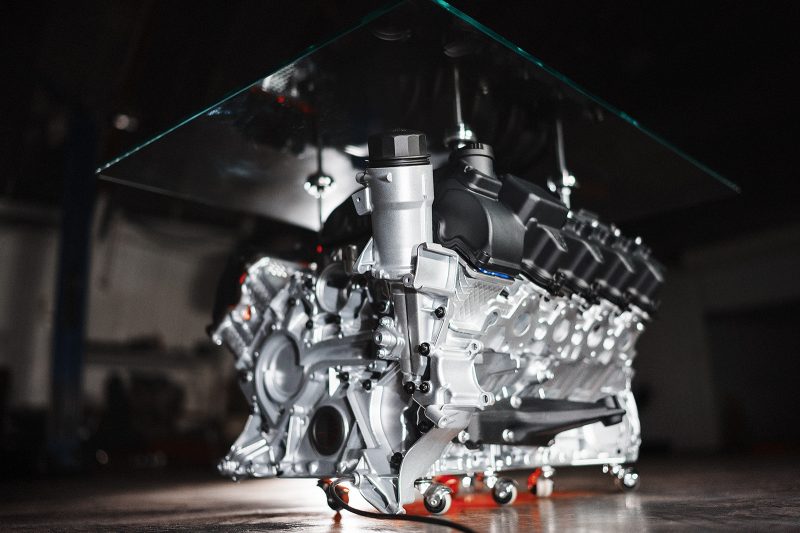

The M113 engine, produced at the Stuttgart-Bad Cannstatt Plant, is a highly-regarded power unit that was in production from 1998 to 2011. This V8 engine, constructed with an aluminum cylinder block, features an injector fuel system, and a configuration that includes 8 cylinders with 3 valves per cylinder. The engine has a bore (diameter of the cylinder) of 97 mm and a stroke (distance the piston travels) of 84 mm, with a compression ratio of 10.

The total displacement of the M113 engine is 4966 cubic centimeters (cc), and it comes with varying power outputs depending on the specific version: 292 horsepower at 5600 rpm, 296 horsepower at 5600 rpm, and 306 horsepower at 5600 rpm. The engine’s torque ranges from 440 Nm at 2700 rpm to 460 Nm at 2700 rpm, with an intermediate version producing 456 Nm at 2800 rpm. The M113 complies with Euro 4 emission standards, reflecting its environmental considerations.

Regarding lubrication, the engine can use various oils, including 0W-30, 0W-40, 5W-30, 5W-40, 5W-50, 10W-40, 10W-50, 15W-40, and 15W-50. The total oil capacity of the engine is 8.0 liters, with an approximate 7.5 liters needed during an oil change. The oil replacement interval ranges between 7000 and 10000 kilometers. The engine operates at an optimal temperature of around 90 degrees Celsius.

Fuel consumption for the M113 engine, when installed in vehicles like the Mercedes-Benz Grand Vitara, is relatively efficient for its class. In urban settings, the consumption is approximately 18.9 liters per 100 kilometers, while on the highway, it drops to around 8.9 liters per 100 kilometers, with a combined average of 13.2 liters per 100 kilometers. Oil consumption is up to 800 grams per 1000 kilometers.

The M113 engine has a practical lifespan of over 300,000 kilometers, although exact figures from the manufacturer are unspecified. When it comes to tuning, this engine has a potential output of over 500 horsepower, highlighting its robustness and adaptability for performance enhancements.

The M113 engine has been installed in a range of prestigious Mercedes-Benz models, including the CL 500 C215, CLK 500 C209, CLS 500 C219, E 500 W211, G 500 W463, ML 500 W163, ML 500 W164, S 500 W220, SL 500 R129, SL 500 R230, and R 500 W251. This versatility and broad application underscore the engine’s performance capabilities and reliability, making it a staple in Mercedes-Benz’s lineup during its production years.

Reliability, problems and repairs of the Mercedes M113 E50 5.0 engine

The older civilian version of the eight-cylinder engines of the M113 family (which also includes the M113 E43 and sporty AMG models M113 E55 and M113 E55 ML) appeared in 1998 as a replacement for the M119 E50. The five-liter power unit M113 E50 is based on the M113 E43 block and together with it is almost a full analog of the M112 E37, but with two additional cylinders and without a balancer shaft.

The cylinder heads are unified with the E37: aluminum, one camshaft per cylinder head (SOHC) and three valves per cylinder (two intake, one exhaust). Inlet valves are 36mm in diameter, exhaust valves 41mm. A variable valve timing system, hydrocompensators and variable-length intake manifold are still used.

The timing drive is chain, chain life is about 200 thousand kilometers. The control system is Bosch Motronic ME 2.8.

The engine was designed for Mercedes models with the index 500.

Mercedes-Benz models were equipped with this engine until 2007, when it was completely displaced by a newer and more modern engine M 273 KE 55. Its history M113 E50 continued on the flagship of the Korean automaker SsangYong.

M 113 E 50 engine modifications

- M113.960 (1998 – 2006) – version with an output of 306 hp at 5600 rpm, 460 Nm of torque at 2700 rpm. It was installed on Mercedes-Benz SL 500 C215 and S 500 W220.

- M113.961 (1998 – 2001) – analog of M 113.960 for Mercedes-Benz SL 500 W129.

- M113.962 (1999 – 2007) – version with an output of 296 hp at 5600 rpm, torque 456 Nm at 2800 rpm. It was installed on Mercedes-Benz G 500 W463.

- M113.963 (2001 – 2006) – analog of M 113.960 for Mercedes-Benz SL 500 R230.

- M113.964 (2001 – 2007) – version with an output of 292 hp at 5600 rpm, torque 440 Nm at 2700 rpm. It was installed on Mercedes-Benz ML 500 W163 and ML 500 W164.

- M113.966 (2002 – 2005) – analog of M 113.960 for Mercedes-Benz S 500 4Matic W220.

- M113.967 (2003 – 2006) – analog of M 113.960 for Mercedes-Benz E 500 W211 and CLS 500 C219.

- M113.968 (2002 – 2006) – analog of M 113.960 for Mercedes-Benz CLK 500 C209.

- M113.969 (2003 – 2006) – analog of M 113.960 for Mercedes-Benz E 500 4Matic W211.

- M113.971 (2006 – 2007) – analog of M 113.960 for Mercedes-Benz R 500 W639.

Problems and disadvantages of Mercedes M113 5.0 engines

Aluminum-silicon alloy cylinders:

- Plus: The alloy has a low coefficient of friction, which contributes to better heat conduction and durability. This makes the engine more efficient and durable when used properly.

- Minuses: The alloy is sensitive to overheating and inadequate loading on an unheated engine, which can lead to cylinder scoring. However, these problems can be easily avoided by following simple recommendations: warm up the engine, avoid high loads until it reaches operating temperature, keep the cooling system in good condition, change the air filter regularly and monitor the pressure in the lubrication system.

Two plugs per cylinder:

- Benefits: Two plugs per cylinder provide more efficient combustion by creating two flame fronts. This allows the engine to run on leaner mixtures, improving fuel economy and reducing emissions.

- Cons: The increased number of plugs requires a higher replacement cost, which can be a problem for those with limited funds.

Variable-length intake manifold:

- Pluses: The variable-length intake manifold system makes the engine efficient over a wide rpm range, providing optimal performance at different speeds.

- Minuses: Over time, the flapper axles can become loose and start to make noise. However, this problem can be solved by repairing the flaps yourself at no significant cost.

Carter Gas Ventilation System (CGVS):

- Pluses: Proper functioning of the CVVS reduces oil build-up and keeps the engine clean.

- Minuses: The system is prone to clogging, especially when poor quality oil is used or not changed regularly. Solutions include cleaning the microscopic holes in the valve covers and replacing all the hoses in the ICS.

Important points for engine longevity

- Maintain the cooling system: Flushing radiators and keeping the cooling system in good condition will help prevent engine overheating and damage to the aluminum-silicon alloy of the cylinders.

- Change the air filter regularly: Changing the filter regularly is especially important when operating the vehicle in dusty conditions. Dust can act as an abrasive and accelerate the wear of the cylinder-piston group.

- Maintain lubrication system pressure: Install a pressure gauge to monitor this important parameter.

- Change timing elements: Timely replacement of the chain, calipers and other timing elements will prevent metal chips from entering the oil sump and ensure engine longevity.

The M113 engine from Mercedes-Benz has many advantages, including high efficiency and reliability. However, its longevity is directly dependent on proper operation and timely maintenance. By following simple recommendations, owners can avoid serious problems and enjoy all the benefits of this outstanding motor.

Oil and Coolant Level Sensor Problems

Some owners experience problems with incorrect oil and coolant level gauge readings. These problems can be resolved by keeping the washer fluid level low and checking the levels of all fluids regularly.

Following these recommendations will avoid most problems and ensure long and trouble free operation of the M113 engine.

Mercedes M113 engine tuning

Compressor

The easiest way to increase the power of your M113 would be to buy an M 113 E 55 AMG or M 113 E 55 ML AMG engine with compressor, initially more powerful and with reliable tuning motors. If replacing the powerplant is not in the plans, then it is worth putting a compressor on your atmospheric M113. The market offers a wide range of manufacturers with various kits that are put on the standard piston and at a pressure of 0.5 bar can increase the output to ~450 hp. The only problem is the high cost of the compressor kit, otherwise their reliability is not in doubt.

To finalize the atmospheric engine with sports camshafts, intake/exhaust and other things, there is no great sense, because the power similar to the compressor version for urban operation can not get, and the costs will be very serious.

ENGINE RATING: 4+