The engine trots. It is usually said so when the engine begins to work unevenly, not “strobing” like a good sewing machine, and allows interruptions with a frequency multiple of the speed.

And this is most clearly manifested in a four-cylinder motor. If the number of cylinders is greater, the influence of one cylinder becomes less noticeable on the general background. Up to the fact that the eight-cylinder engines, for example, the car ZIL-130, do not always pay attention to one non-working cylinder: it is simply not noticed.

Engine troit (engine troenie) – a definition that should be understood as a failure in the operation of the internal combustion engine, when one or more cylinders do not work partially or completely. To put it differently, the process of combustion of the fuel-air mixture in individual cylinders is broken, which causes unstable operation of the engine at idle, under load and in transient modes.

Engine thrashing manifests itself in the form of increased vibrations of the power unit, the engine noticeably loses power. There may be ignition misses, which are accompanied by strong pops in the exhaust system. The motor can troche both occasionally and constantly, only at idle or under load, on cold, on hot, etc. Next, we intend to answer the question of what is the trolling of the engine, as well as to consider the main reasons why the motor begins to trot.

Why the motor begins to trot

So, what is the cause of modern gasoline engine with a distributed fuel injection system?

Let’s start with the fact that the engine trojan is a violation of the combustion of the mixture in the cylinders, which is accompanied by an obvious increase in vibration. Note, the appearance of internal combustion engine vibrations is not necessarily a ternary, as there are a number of other reasons why the engine strongly vibrates.

In the list of the main faults, as a result of which the engine trots, noted:

- feeding insufficient or excessive amounts of fuel into the cylinder;

- feeding insufficient or excessive amounts of air;

- ignition system malfunctions, early or late ignition;

- motor wear or breakdown, which is accompanied by a decrease in compression;

In other words, the motor begins to trojan as a result of inappropriate composition of the fuel-air mixture, untimely ignition of the mixture or lack of opportunity to ignite the charge, as well as violation of the conditions of normal combustion of the mixture as a result of mechanical wear or breakage of the engine itself.

Based on this data, you can narrow down the range of search and the number of systems to be diagnosed. Start the check with the fuel system and injector, then check the inlet air supply and the ignition system. In some cases, engine trolling can also be the result of a failure of one of the sensors of the electronic engine management system.

Fuel system of a car with a gasoline engine

The most common cause that causes the engine to trot is late or early ignition, as well as weak spark of the spark plug. The initial step is to unscrew the spark plugs for a detailed inspection. If damage to the insulator or other defects are noticeable, then the plug should be replaced.

In the case of a damaged insulator, the place of damage is clearly visible, as this area turns black. You should also pay attention to the condition of the center electrode and assess the gap of the side electrode.

Next, it is necessary to check the plug wires. An indirect sign indicating this element is the occasional tethering of the engine in conditions of high humidity (rain, damp, etc.). After the engine warms up and reaches operating temperature, the symptoms may completely disappear.

Start by inspecting the plug cap and the high voltage wire itself. These elements have rubber insulation, which tends to dry out and crack over time, as a result of which the wire begins to break through.

Also, the high-voltage wire or cap is often damaged during service or repair work in the underhood. We should add that the place of breakdown visually can not be detected. In this case, it is better to check this element of the ignition system in one of the available ways.

If everything is in order with the plugs and wires, then the culprit of the fact that the engine trots, may be the ignition coil. On motors with separate coils for each plug, this phenomenon is particularly common. To check the ignition coil it is necessary to unscrew the plug, put it to the mass and start the engine. Pay attention, the thread of the plug should be tightly touching the mass, the cap should be tightly put on the plug. Ignoring these rules can lead to burnout of the coil or commutator. Good spark with a characteristic crackle will be evidence of the coil serviceability, the lack of spark will indicate the need to replace the coil.

As for the electronic ignition distributor (commutator), this element is not often broken. To check the plugs are securely fastened to the mass, then they connect the caps, after which one person turns the engine with the starter, and the other assesses the strength of the spark on the plugs.

Motor thrashing: problems with the air supply

Insufficient air supply at the intake or an excessive amount of air can also cause a cylinder trolling. The air supply system can lose its tightness and the engine starts sucking in excess air. The ECU does not take into account this suction, as a result, the stability of operation is disturbed.

It is quite easy to check the air system. It is necessary to tightly close the intake tube next to the air filter, then pump air to create a pressure of about ½ atmosphere, then look for a leak. In case the pressure does not drop, then the system is tight. The appearance of a hissing sound of escaping air allows you to identify the problem area, through which the motor sucks excess.

Lack of air is often caused by a dirty air filter that has lost capacity. The filter should be removed and the engine performance should be evaluated after removal. Also, the air may be insufficient in the event that the throttle plate is clogged or there are malfunctions in this assembly. The specified element requires mandatory cleaning and inspection. It is desirable to do this at each scheduled maintenance in parallel with the replacement of engine oil, filters, etc.

Another cause of engine thrumming may be a throttle position sensor, mass air flow sensor or another sensor that gives an incorrect signal to the ECU. The ECU in such a situation does not know by what degree the throttle is actually open, how much air actually entered the engine, etc. Based on incorrect data “brains” can not accurately calculate the optimal composition of the fuel-air mixture in relation to dynamically changing modes of operation of the internal combustion engine.

In this case, it is necessary to view the sensor readings and read errors with a scanner, which is connected to the diagnostic socket of the car. Then the values should be compared with the nominal values. Deviations from the norm in the readings of the airflow meter or the throttle position sensor lead to the fact that the engine begins to trojan.

Trottling by cylinder: faulty power system

The following points should be noted when checking the power system:

- fuel pressure;

- air suction;

Fuel pressure directly depends on the serviceability of the electric gasoline pump, which on modern injector cars is located in the fuel tank. The device may be clogged mesh-filter of the gasoline pump, there may be problems with the electric motor of the fuel pump or power supply to the pump. It is also worth checking the pressure regulator valve in the fuel ramp. Low pressure in the fuel supply system is often the cause of the trolling.

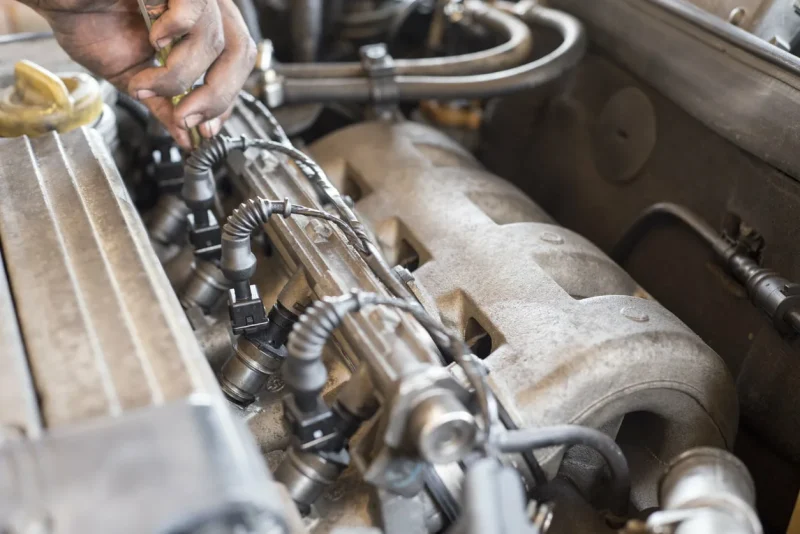

The next step is to check the injector injectors. This element tends to be clogged, resulting in reduced flow capacity, violates the shape of the atomization torch, etc. Also do not exclude the failure of the injector itself. To clean and check the injectors, you can use a flushing stand, where a special flushing fluid is pumped through the device and the power is supplied. Under such conditions, the work of the injector on the engine is simulated, performance is evaluated, etc.

A serviceable injector should not leak in the closed state. Also, the injector should open in time when an electrical impulse is applied. It is not allowed that the injector pours fuel, since the efficiency of the subsequent combustion of the charge in the cylinder depends on the quality of the atomization.

If the fuel pressure and the injector itself are in order, then the ECU should be checked. The ECU itself fails rarely, but it is possible. More often it happens in cases where the factory firmware was changed when installing the HBO or the motor was made program chip tuning. Unprofessional manipulations with fuel cards can lead to the fact that the ECU overfills the fuel and fills the spark plugs.

A drop in compression indicates engine malfunction or wear and tear. One or more cylinders partially or completely fail, so fuel and air are supplied, but the mixture is not properly compressed. In this case, normal combustion does not occur. Compression drop occurs due to burned-out pistons or valves, heavy wear of piston rings and other defects of the BC, cylinder head or timing elements.

In this case, it is necessary to measure the compression in the engine, after which the unit is disassembled for detailed diagnosis and repair. In conclusion, we would like to add that the operation of the engine with an inoperative cylinder is prohibited, as driving with such a malfunction leads to a number of additional problems, which significantly complicates and makes more expensive the subsequent repair.